The principle of sodium hypochlorite sterilization

The main action of sodium hypochlorite disinfection is to form hypochlorous acid through its hydrolysis, and hypochlorous acid is further decomposed to form new ecological oxygen [O]. The extremely strong oxidizing nature of the new ecological oxygen denatures the proteins and other substances on bacteria and viruses. , Thereby lethal pathogenic microorganisms. Secondly, in the process of sterilization and virus killing, hypochlorous acid can not only act on the cell wall and virus shell, but also because the hypochlorous acid molecule is small and has no charge, it can also penetrate into the bacteria (virus) body and interact with the bacteria (virus) body. Organic polymers such as proteins, nucleic acids and enzymes undergo oxidation reactions to kill pathogenic microorganisms. Third, the chloride ions produced by hypochlorous acid can also significantly change the osmotic pressure of bacteria and virions, causing cells to lose activity and die.

Summary of the principle of sodium hypochlorite generator

The main reaction process of sodium hypochlorite generator electrolysis can be expressed by the following equation:

NaCl+ H2O = NaClO + H2↑

Electrode reaction: anode: 2Cl--2e- → Cl2 cathode: 2H2O + 2e- → H2 + OH-

Solution reaction: 2NaOH + Cl2 → NaCl + NaClO + H2O

The electrolysis process of the electrolytic brine type sodium hypochlorite generator is an electrochemical reaction process. Its only raw materials are salt and water. The sodium hypochlorite solution is made of pure quality. Although the chemical principle is simple, there are many technical indicators that affect the economy. So sodium hypochlorite occurs The design of the electrolysis electrode of the electrolytic device should consider various factors, and design and manufacture according to the characteristics of compact and reasonable structure, energy-saving operation, convenient operation and maintenance, high reliability of operation, and long service life of the equipment. The sodium hypochlorite solution is accurately dosed, safe to operate, easy to use, easy to store, non-toxic to the environment, and there is no air leakage, and it can be dosed under any environmental working conditions.

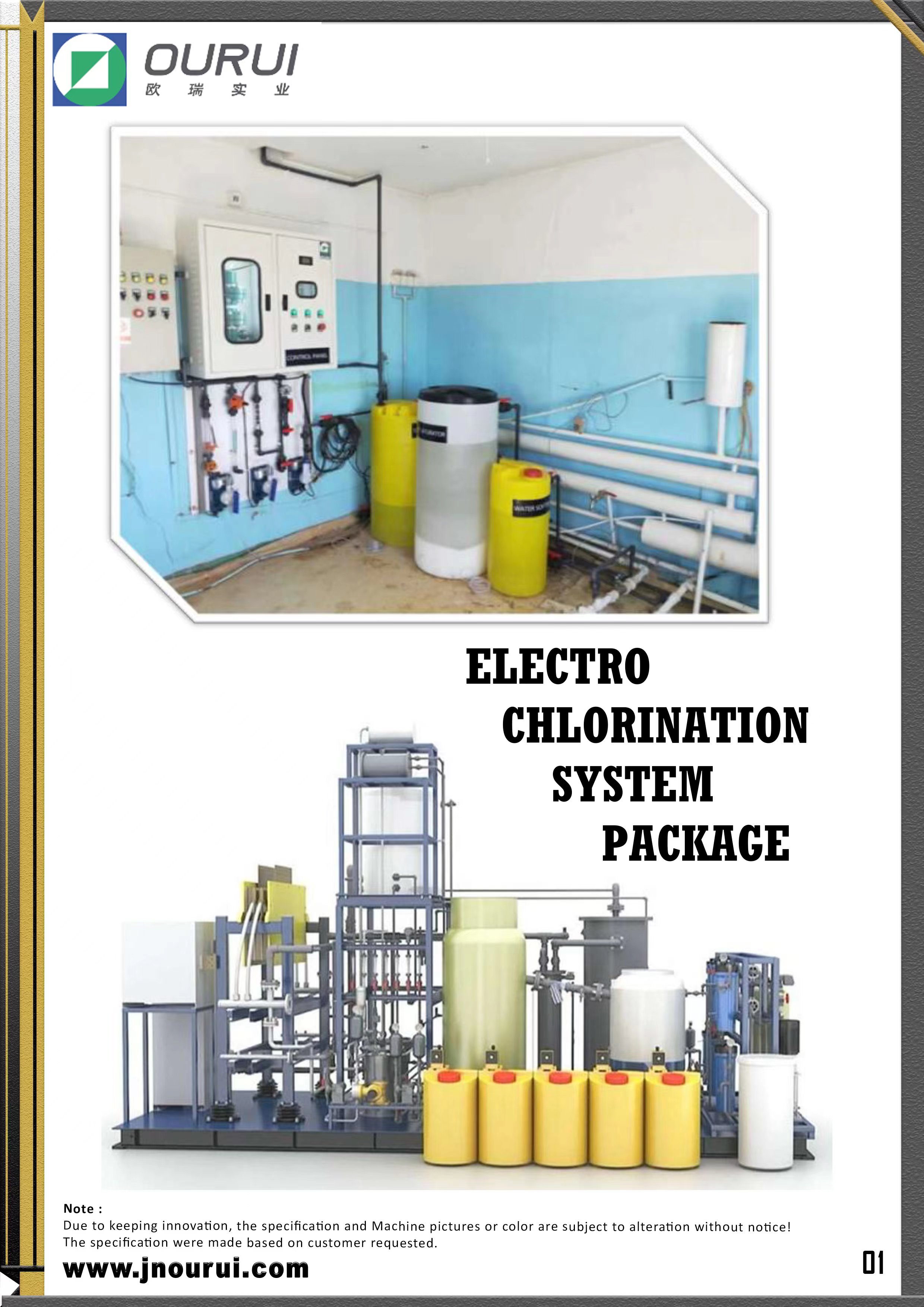

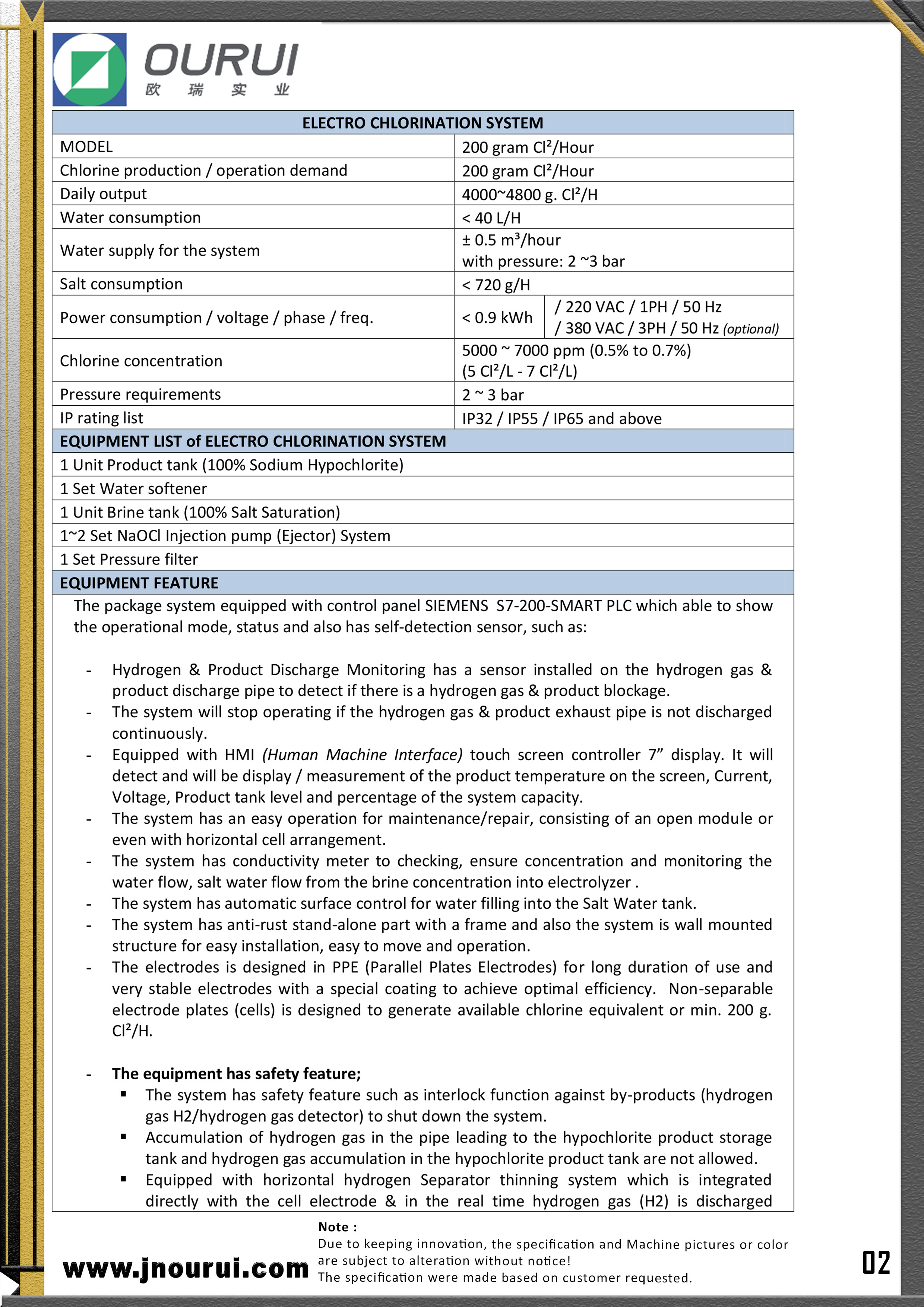

System composition :

1. Soft water unit; 2. Saturated brine preparation unit; 3. Dilute brine proportioning unit; 4. Electrode electrolysis assembly unit;

5. Rectifier power supply unit; 6. Control system unit; 7. Storage unit; 8. Hydrogen exhaust unit; 9. Dosing unit;

Features:

1. The installation is quick on site, and the installation is completed in only 4 hours if the conditions are met. On-site installation only requires 4 steps:

(1) Connect to the tap water pipeline;

(2) Switch on the power supply;

(3) Connect the chlorination pipeline;

(4) Install hydrogen exhaust pipe

2. The "reverse electrode technology" is used to protect the electrode from pickling.

Optional accessories:

1. Photovoltaic system: It can be equipped with photovoltaic power generation device to provide electrolytic power. The photovoltaic effect of the semiconductor interface is used to invert light energy into electrical energy, which is mainly composed of three parts: solar panels, controllers and inverters.

2. Internet of Things: realize logistics network communication, remote real-time display or intervention of equipment working status, remote monitoring and diagnosis

Application areas:

|

Municipal

|

Safe drinking water in rural areas

|

|

District secondary water supply disinfection

|

|

University teaching experiment and campus drinking water disinfection

|

|

|

Hospital sewage disinfection

|

|

Food processing

|

Food processing plants

|

|

Other

|

Greenhouse planting

|